| Scott's Atlas / Craftsman 101.07403 12x36" Lathe, modifications and projects. Stone Mountain, GA | Unique Visitors: |

|

This is a picture of when I ground my Atlas 3-jaw chuck. From some steel, I cut some wedges; basically some flat stock with a slot cut in them to make them a bit "springy." They were inserted between the jaws and the chuck tightened. Then a Dermel was mounted on the tool post. I uses a small grinding disc and did several passes at about 0.002" until all the jaws showed the same contact with the wheel. Then some final passes without further advancing the wheel. The jaws were bell-mouthed and I had about 0.008" runout. Stock would just never sit straight. Now I get about 0.002 to 0.004 runout; what I would expect on a 3-jaw chuck. It will never be perfect but at least now it is not way off and the pieces are straight. The picture was taken with the chuck turning slowly and I did use an auto feed in both directions. |

|

I'm on my 3rd pump up sprayer. I use them a few times then the valve breaks or plugs up. This one was the same. Fed up with needing to buy another, I decided to replace the valve with a good one. I took the handle apart and threw out the old valve. A 1/8" brass ball valve was used. The handle was tapped with an 1/8" NPT thread using a standard tap. I made the white part on the lathe using delron 3/4" stock. First it was drilled to match the white tube OD. The the outside turned to match the thread outer diameter. I then cut the 1.5mm threads on the lathe with a 60-degree tool. Finally the part was tapped with an 1/8" NPT tap. Now it won't plug up ;) Even if it did, I can take it apart and clean it. |

|

Some mystery parts that came with the lathe: #1 - Identified as an arbor to mount a standard drill chuck in an old hand drill (the crank handle type.) #2 - Still unknown. Seems to fit over the lantern post. My guess it keeps the post from moving when the set screw is loosened. #3 - Unknown #4 - Cross slide nut (and is worn.) #5 - either a very small gear puller or a puller for clock hands. #6 and #7 - seems to be some kind of follower. |

|

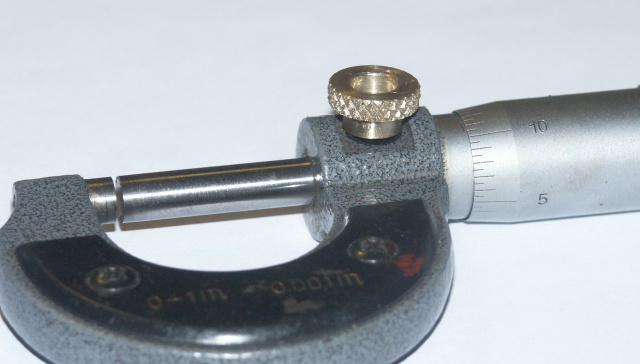

The plastic knob on my 0-1 micrometer broke. So, I made a small brass knob. Just a few minutes to do. Dill for press fit on old stud. Knurl outside. Turn step and then drill reverse for screw. |

|

An adapter to fit the normal 1/4 R-12 gauges on the smaller port on my Jeep. |